DELTA Rotary Screens from GURJAR are the result of constant research and development giving a first class technological product. DELTA screens with their Higher Thickness and Higher Open Area find universal applications for printing both large surface areas as well as outlines and details.

DELTA® screens are meant for textile printing better colour find distribution, consistent colour deposition, more exact reproduction of fine details and the possibility of printing fine outlines and straight lines without any saw tooth effect. DELTA screens reflect to better printing economics due to lower dye paste consumption, higher printing speeds and lesser screen wear with highly corrosive printing pastes.

DELTA 110 - The Screen - Power to print Universal Rotary Prints

GURJAR introduced Delta Rotary Screens in the year 1990, since then they have started receiving growing success among various type of Rotary Printers. From the whole range of DELTA Screens, the Rotary Printers have greatly appreciated the Delta 110 mesh screens and named them Universal Screens due to the possibility of printing large blotches to very fine details with just one screen.

According to them, Delta 110 mesh screens are ideal replacement to conventional 125 mesh screens having following distinct advantages.

- Easily strippable after polymerization and printing - Not so in the case of 125 mesh.

- Pinning and Retouching made easy due to large open area and hole diameter - Not so in the case of 125 mesh.

And other distinct possibilities & applications make these screens Universal & Highly Economical Screens.

The new Delta 110 Mesh offers universal applicaitons as follows :

- Large Blotch Printing: Even colour distribution and brilliancy of shades without Moire effect.

- Fine and Straight lines: With higher mesh and higher open area, minimizing the saw tooth effect.

- Half Tone Printing: Clear reproduction of finest details due to high resolution of screen.

- Discharge Printing: Greater Dye penetrability giving better and deeper discharge effect, thanks to higher open area.

DELTA 125 HTS & 155 HTS

Convenient Screens especially suited for half - tone printing. These Screens with adequately less O.A. % than conventional screens used for this purpose facilliate better, sharper half - tone print effects using suitable magenta contact screens or raster.

DELTA Non Textile Rotary Screens

We also offer higher thickness, higher open area Delta rotary screens for coating and bonding applications in screen's lengths from 900 mm to 3500 mm in 14, 25, 40, 60, 70, 80, 100, 125, 155 & 185 mesh count.

| REPEAT | 640 | 640 | 640 | 640 | 640 | 640 |

|---|---|---|---|---|---|---|

| MESH | 110 | 125 | 125HTS | 155HTS | 155 | 185 |

| PKG | 20 | 20 | 20 | 20 | 20 | 20 |

Delta® SV

In continuation to our endeavour to offer our Rotary Textile Printers better and effective solutions for their rotary screen printing machines, we have the pleasure of announcing the introduction of new screens in our DELTA range of Nickel Perforated

These Screens with their special 45o mesh angle make them ideally suited for all types of geometrical designs. This coupled with our seamless digital lacquer and direct light laser engraving facility help in getting sharper prints for their geometrical patterns. Technical specifications of 125 SV DELTA and 155 SV DELTA are the same as regular 125 DELTA and 155 DELTA. They differ in their mesh angle at 45 o instead of regular 60 o, specially created by Gurjar's R & D Team.

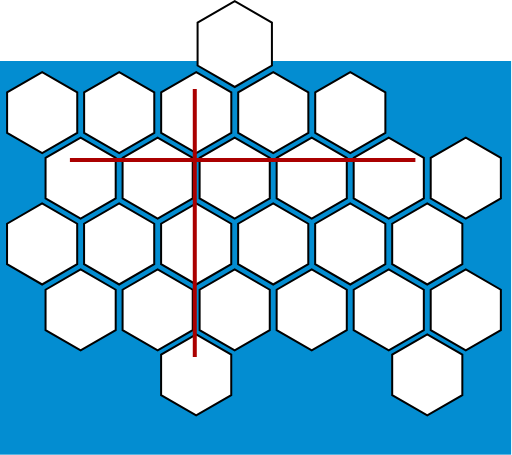

Regular Mesh 125 & 155

with 60o Angle Mesh

suitable for half tone designs

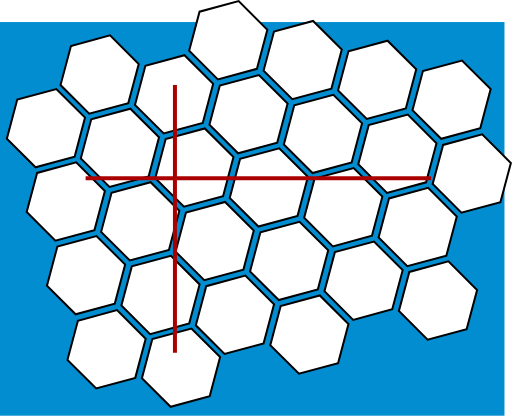

125 SV & 155 SV Mesh

Special screen with 45o Angle Mesh

suitable for geometrical designs